With our many years’ experience in injection moulding and mould tool design we can assist our customers throughout the design process from a basic concept through to the manufacturing and production of quality products.

Whether you are at the initial stage of concept and need help in designing your component for injection moulding or at the final stage where you have a proven component design and CAD we can help guide you through the process to production to give our customers the best overall solution for their plastic moulded components.

If you have you own designers or design house, then that is fine too we will happily work together to achieve the best possible outcome.

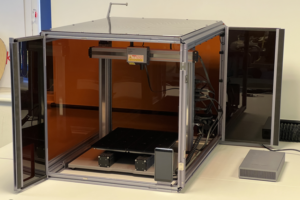

Prototyping can be a key stage in the design and development process, we can use 3D printing in a wide range of materials and resins to help prove design concept and functionality prior to proceeding onto mould tool manufacture.

We offer onsite 3D printing and work with other 3D sample specialists to prepare in the most appropriate process for samples that will help prove your design. Whilst sample parts may not exactly replicate the mechanical properties of production parts, they are useful for verifying product fit and function.

Project management is a key part of any development process we collaborate with our customers to agree timelines and project milestones to ensure all project run smoothly keeping them informed of any critical issues that may arise and go that extra mile to deliver within an agreed budget and always on time.

We work with a host of high-quality subcontractor toolmakers but having our own mould tool design, manufacture and injection moulding under one roof allows for a quick and easy tool trial process meaning we can run T1 and T2 trials parts quickly, whilst making any changes to ensure the mould tool and components run at optimum desired output when in production.